Oxidizer Cost Comparison for Soil Vapor Extraction

April 2, 2019 8:52 am[/vc_column_text]

Oxidizer Cost Comparison for Soil Vapor Extraction

When selecting the Best Available Technology (BAT) for Soil Vapor Extraction (SVE) air abatement applications, it is of great value to understand the potential exponential decay that might be expected. In typical SVE applications, 60% to 90% of the available mass of Contaminates of Concern (COC) are removed within months after starting up at concentrations of 100% to 25% of the Lower Explosive Limit (LEL). The longest period of operation for SVE and Oxidizer systems is after treatment of the initial high loadings with LELs between 30% to 2%. Depending on the oxidizer technology, this may require supplemental fuel – such as natural gas or propane – to keep the oxidation system at regulatory operating temperature.

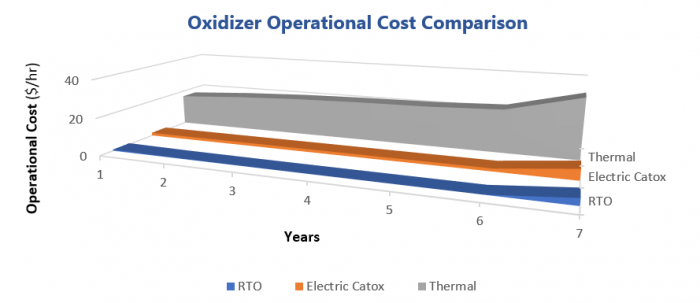

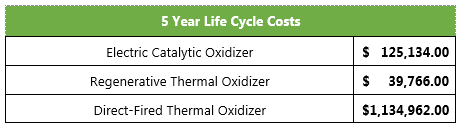

Below is an Oxidizer Operational Cost Comparison for a 500 SCFM SVE system required to process an initial 100 lbs/hr with normal decay over a five-year total time clean up goal. The graph shows cost comparisons among three different pollution control technologies: a Direct Fired Thermal Oxidizer (Gray), an Electric Catalytic Oxidizer (Orange), and a Regenerative Thermal Oxidizer (Blue).

An RTO was selected as the BAT for this project because it was able to manage the initial high loadings as well as automatically adjust as concentrations decayed. Additionally, the overall supplemental fuel costs over 5 years was significantly lower than traditional oxidizer solutions used in SVE applications.

In the past, an RTO was not viewed as the best technology for 300 to 2,000 SCFM SVE applications due to the fact they could not be built with low NOx burners and appropriate air flow mixing in order to achieve destruction efficiencies over 95%. Ship & Shore Environmental has low volume designed RTO systems for any SVE project. Depending on the application, the heat recovery media can be altered over the life of a project, making RTOs the most cost-effective and self-sustaining oxidization technology.

Ship & Shore Environmental can assist you with an agnostic cost-analysis comparing any APC solution. Visit our website for more info on RTO Technology, Oxidizers for SVE Applications, Remediation Solutions using traditional technologies, or Treatment Solutions for Contaminates of Concern or call (562) 997-0233.

Categorised in: Energy