#TechTalk: RTO Ceramic Heat Exchange Media Health

December 17, 2025 9:35 am#TechTalk: RTO Ceramic Heat Exchange Media Health

December 17, 2025

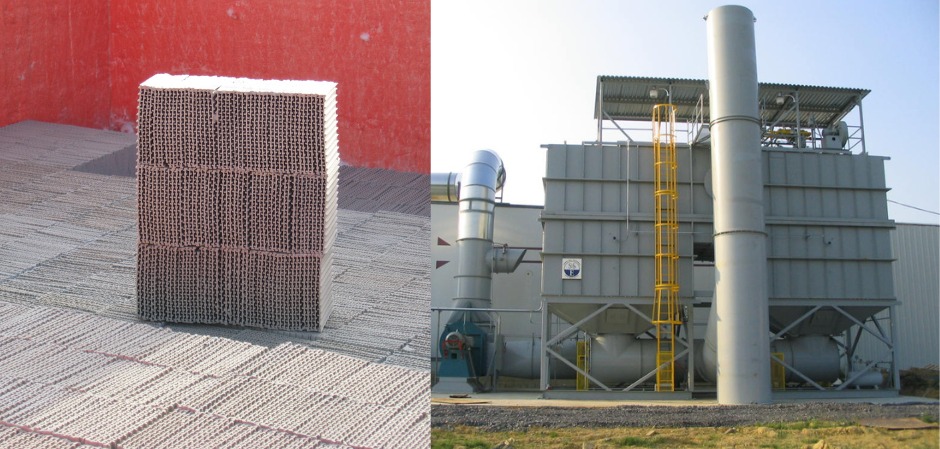

Regenerative Thermal Oxidizers (RTOs) rely on the “three Ts” for effective VOC, HAP, and odorous air treatment: sufficient residence time, proper oxidation temperature, and adequate turbulence to ensure thorough mixing. When these factors are balanced, RTOs deliver reliable and efficient emission control.

Even well-maintained RTOs can face performance issues due to the condition of ceramic heat exchange media.

Chemical exposure, particulate loading, and condensate formation can gradually compromise media integrity. Common problems include accumulation of organic or inorganic deposits, chemical attack that fractures or degrades media, unintended chemical transformations (e.g., organo-silicate converting to silica dust or glassy residues), condensate buildup, and media settling that may cause partial or full plugging.

These issues restrict exhaust flow, reducing volumetric throughput and heat recovery efficiency. Higher restriction increases pressure drop across the media, raising electrical demand on induced draft fans and motors. At the same time, fouled media or airflow channeling reduces heat transfer efficiency, causing higher natural gas consumption as burners compensate. Changes in pressure drop, energy usage, or destruction efficiency often signal early media problems.

Some issues, such as chemical attack or long-term settling, usually require partial or full media replacement. Other problems, like particulate fouling or condensate accumulation, can often be addressed with controlled wash-out procedures or oxidizer bake-out routines. Proper identification of fouling materials ensures safe and effective treatment.

Media wash-outs are performed offline with cooled RTOs. High-volume, low-pressure water flushes contaminants from the ceramic media. Depending on residue type, wash water may require collection, treatment, or disposal. This restores performance in many cases, though silica-based deposits are harder to remove, and repeated fouling may eventually require media replacement. After cleaning, the system is gradually dried with fresh air before returning to service.

Bake-outs work like a self-cleaning oven, raising internal temperatures to oxidize organic contaminants. They can be conducted online or offline. By extending valve cycle times in one direction, heat penetrates the ceramic bed to burn off deposits; reversing flow treats the adjacent chamber. These procedures must be carefully executed under trained personnel to avoid equipment damage.

Ship & Shore Environmental technicians support customers with best practices to extend the life of RTO ceramic media and other critical components. If media plugging or declining performance is suspected, scheduling a preventive maintenance inspection is a key step to preserving system reliability and long-term efficiency.

📞 Contact us at +1 (562) 997-0233

📧 Email: service@shipandshore.com

Categorised in: #CleanAirSolutions, #MadeInAmerica, #VOC Control, 25Years of S&SE, Ship & Shore, Technical, TechTalk, ThermalOxidizer, VOC Abatement