State-of-the-Art RTO Control Systems Virtual HMI Availability & Upgrade

September 7, 2016 4:48 pmState-of-the-Art RTO Control Systems Virtual HMI Availability & Upgrade

S&SE State-of-the-Art Virtual HMI Controls

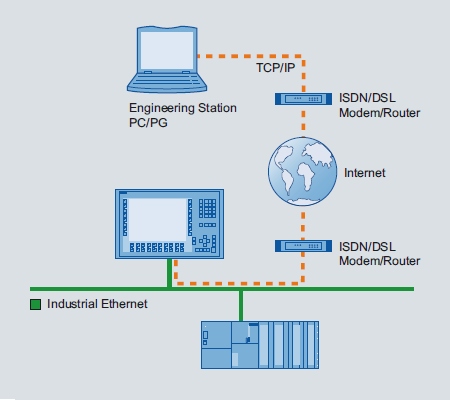

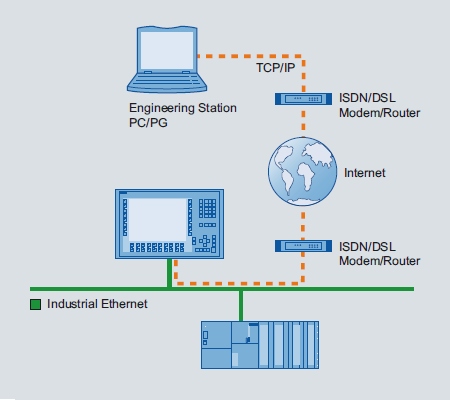

Remote operator control and monitoring of HMI systems via Industrial Ethernet or Internet allows for better access and response time of plant operations.

Benefits

- Distributed operator stations for controlling large machines that are spread out over a large area

- Flexible solution for access to operator stations from any location

- Global access by the service and maintenance personnel to machine/plants.

An on-site operating station can basically be accessed in two different ways.

Display and operation of screens via the Virtual HMI concept

Within the scope of this concept, a station can make its screens accessible to another station. It then assumes the function of an HMI Screen remotely. The server function can be activated quite simply with a mouse-click when making the device settings. The screen can be displayed on the Virtual HMI Screen by means of a display in “View only” mode, but a full-fledged, coordinated operator console can be set up as well. “Coordinated operation” implies that at any one time only one station has the right of operation.

Distributed operator stations

The operation of large, physically distributed machines and plants becomes easier, because distributed operator stations can be configured by means of the Virtual Network Computing concept, so that the operator can control and monitor from various locations – while only needing to configure one time. Changes to the configuration therefore only have to be performed once on the Virtual Network Computing. The operator can see the same display on every operator station, although only one station can be operated at any one time (coordinated operation).

Remote control via Internet Explorer

For remote operating and monitoring, a standard browser, which gives the user direct access to the HMI device on-site via the standard HTML pages of the operating stations, is sufficient. If the HMI Screen is used instead of a browser, it not only displays the selected screen, but also the layout of the on-site device, for example, the membrane front of a keypad device. With this tool, the HMI device can then be operated as if the user were on site, except that the keys are not really actuated, but operated by clicking the mouse.

Optimized Service

The S&SE Virtual HMI also allows our engineering team to assist quickly with remote access to data and logged data to troubleshoot and or offer assistance with any process or compliance issues.

Ship & Shore helps manufacturers maintain compliance with complete environmental solutions for air pollution abatement and energy and heat recovery systems for maximum efficiency and cost effective operations. If you have any concerns, would like to know more about specific OZONE REGULATIONS and how they may affect your business, or just need a little expert advice, please call Ship & Shore Environmental at (562)997-0233 or CONTACT US BY EMAIL

Categorised in: News, News, Technical, Uncategorized