Selective Catalytic Reduction (SCR) System

Ship & Shore Environmental offers Selective Catalytic Reduction (SCR) Systems for processes that require NOx abatement in order to comply with air quality rules and low NOx limits. Depending on the VOCs present in the manufacturing process, Ship & Shore can custom engineer, design, and fabricate an SCR system connected to a Regenerative Thermal Oxidizer (RTO).

General components of an SCR and RTO abatement system include:

SCR CATALYST & INJECTION GRID

SCR catalyst will be located on the RTO stack. A hot bypass will be connected to the RTO stack in order to maintain the temperature between 500°F to 700°F before entering the SCR catalyst. Ammonia will be injected to the stack and mixed with the flow through the injection grid and mixing plate.

The Ammonia and NOx mixture will enter the catalyst media. NOx and Ammonia will react through the catalyst bed and will turn into N2 and H2O. SCR catalyst can be designed for up to 95% NOx reduction efficiency.

AMMONIA VAPORIZOR UNIT

Aqueous ammonia (NH3) will be pumped from a storage tank and will be vaporized by hot air atomization. Vaporized ammonia will be sent to injection grids at about 250°F. An ammonia vaporizer unit typically consists of the following: electrical heater, air blower, ammonia filter, and control system.

Anhydrous ammonia or Urea can also be used instead of aqueous ammonia. There may be some safety concerns associated with the use of anhydrous ammonia. The Urea option will need to have a “Urea to Ammonia” equipment added. The possibility of both options can be studied for any specific process.

ANALYZERS

Online analyzers are available to monitor NOx or Ammonia slips at the exhaust stack. It is also important to control the ammonia injection rate based on NH3 or NOx slip. A signal from the analyzer will be used to control the ammonia injection rate.

A laser cross-duct in situ NH3 gas analyzer can be used to monitor ammonia slip and chemiluminescent analyzer can be used to monitor NOx. The analyzer system usually includes sampling system, probes, and analyzer enclosures.

AMMONIA TANK AND PUMP

An ammonia tank and pump will be needed to store ammonia and pump it to the vaporizer. The tank can be sized based on available space and loading frequency. For example, a 1000-GAL tank will have a hold up of 1-2 weeks at maximum NOx concentration or about 3 weeks at an average NOx concentration.

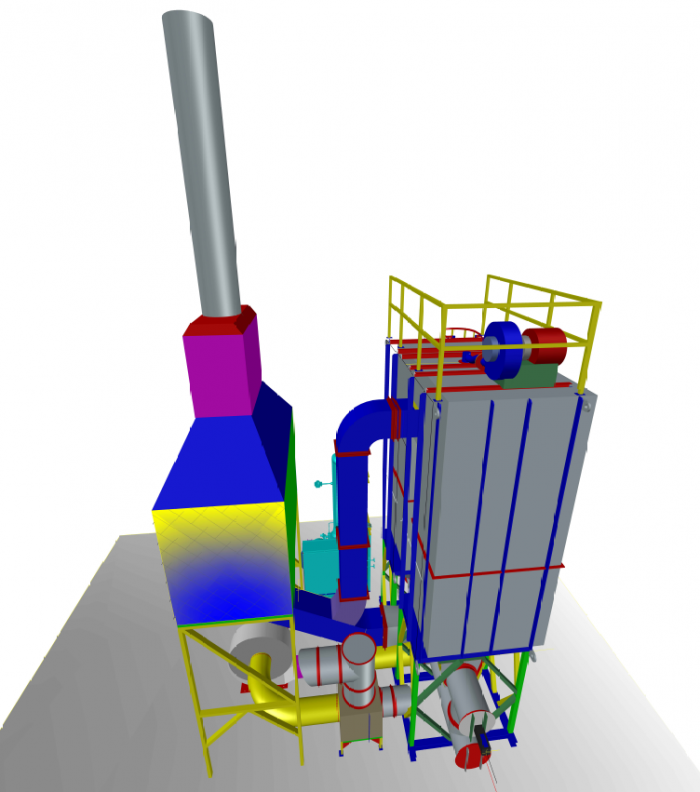

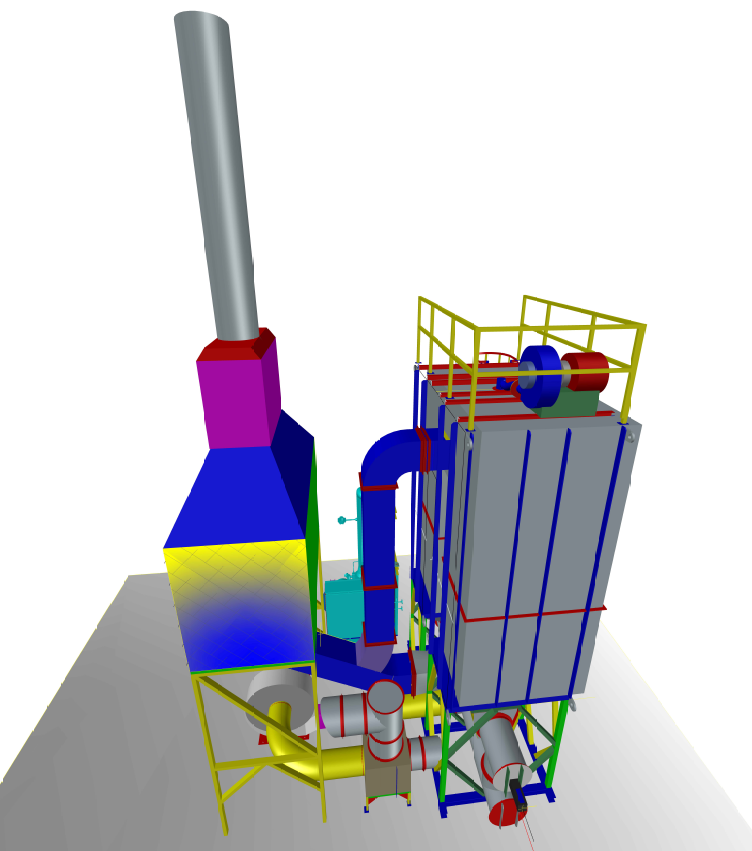

Fig. 1 – 3D Rendering of a Ship & Shore RTO (left) + SCR System (right)

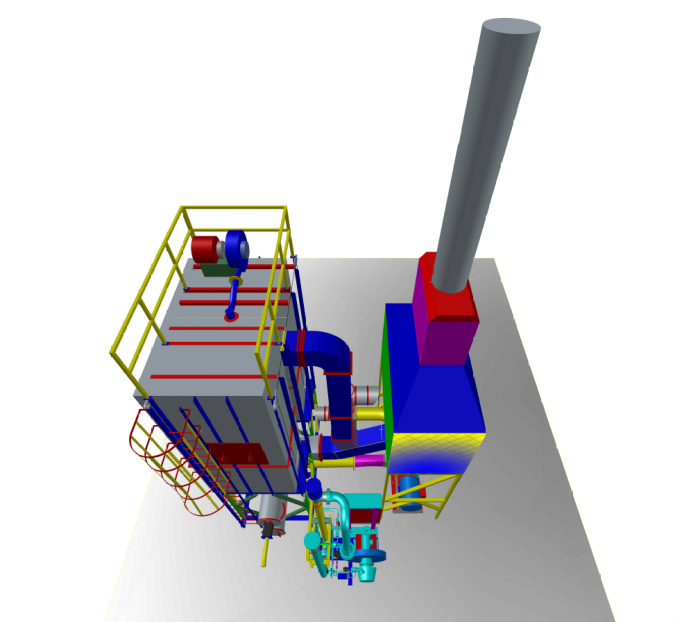

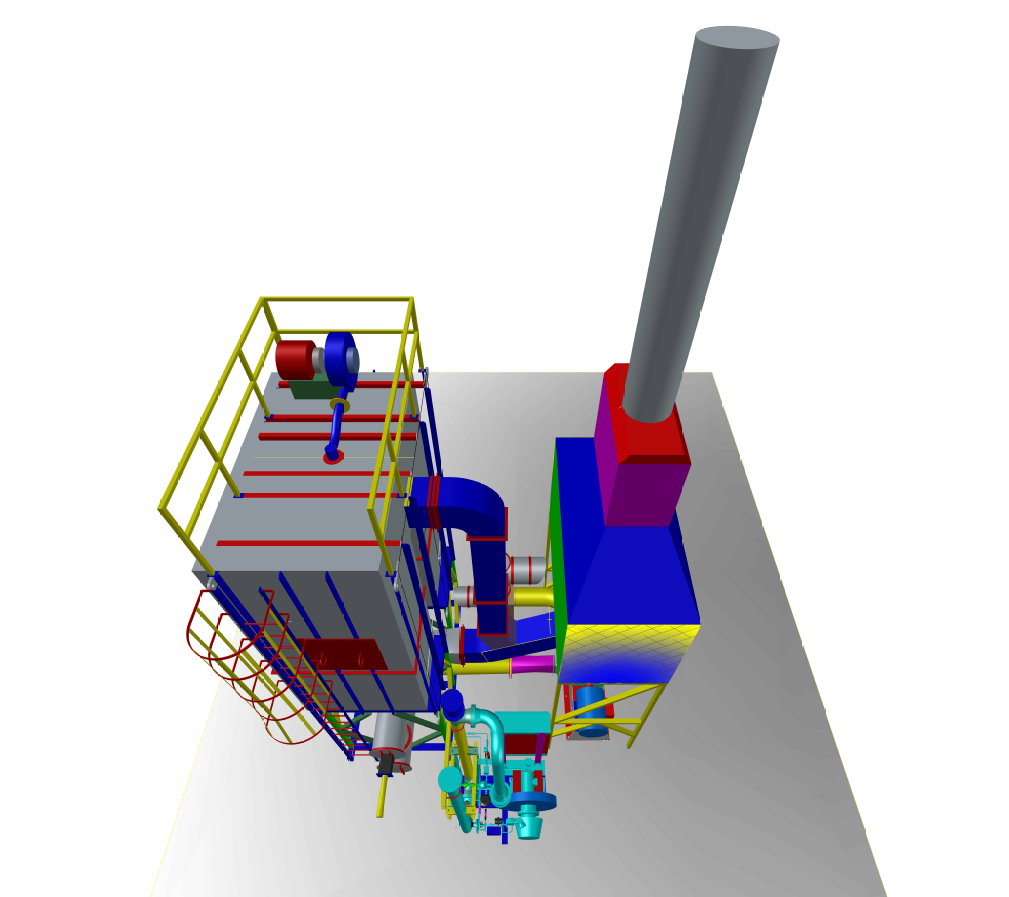

Fig. 2- 3D Rendering of a Ship & Shore RTO (right) + SCR System (left)