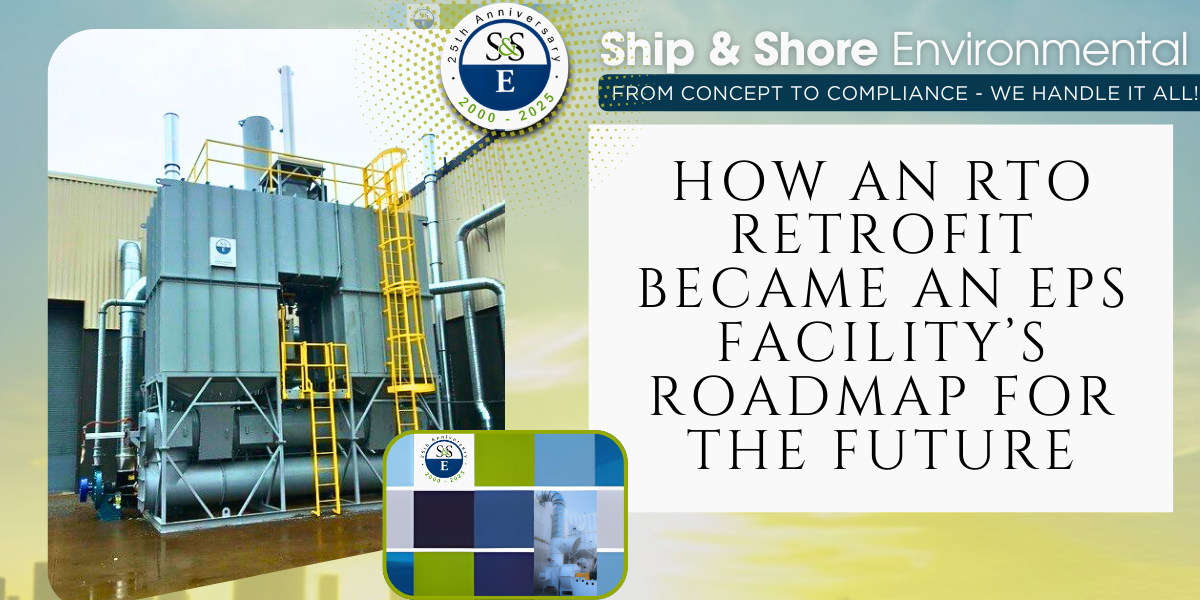

How a 17,000 SCFM Retrofit Became a Game-Changer for an EPS Manufacturer

May 15, 2025 8:35 am

How a 17,000 SCFM Retrofit Became a Game-Changer for an EPS Manufacturer

Intro:

When growth pushes production to new heights, rising emissions can spell disaster. One EPS manufacturer faced this very challenge—until a custom RTO retrofit from Ship & Shore Environmental provided the perfect solution.

The Quick Story:

Increased output meant more pentane emissions, jeopardizing compliance and efficiency. Ship & Shore stepped in with a tailor-made 17,000 SCFM Regenerative Thermal Oxidizer retrofit designed to:

- Deliver 98% VOC destruction

- Recover 95% of thermal energy

- Integrate seamlessly with existing equipment

- Boost energy efficiency while ensuring full regulatory compliance

Why You Should Care:

This retrofit isn’t just a piece of equipment—it’s a blueprint for growth without compromise. It showcases how strategic innovation can keep your operations efficient, compliant, and ready for the future.

Want the Full Story?

Discover how we turned an emissions headache into a roadmap for success. Click the link below to dive into our complete case study and see how your facility can benefit from the same cutting-edge solution.

👉 Read the full case study: https://shipandshore.com/case-study-how-an-rto-retrofit-became-a-roadmap-for-the-future-of-one-eps-facility-a-17000-scfm-story/

Categorised in: Blog