HEAT EXCHANGERS AREN’T OPTIONAL — THEY’RE ESSENTIAL

July 21, 2025 5:00 amAftermarket Mondays: HEAT EXCHANGERS AREN’T OPTIONAL — THEY’RE ESSENTIAL

July 20, 2025

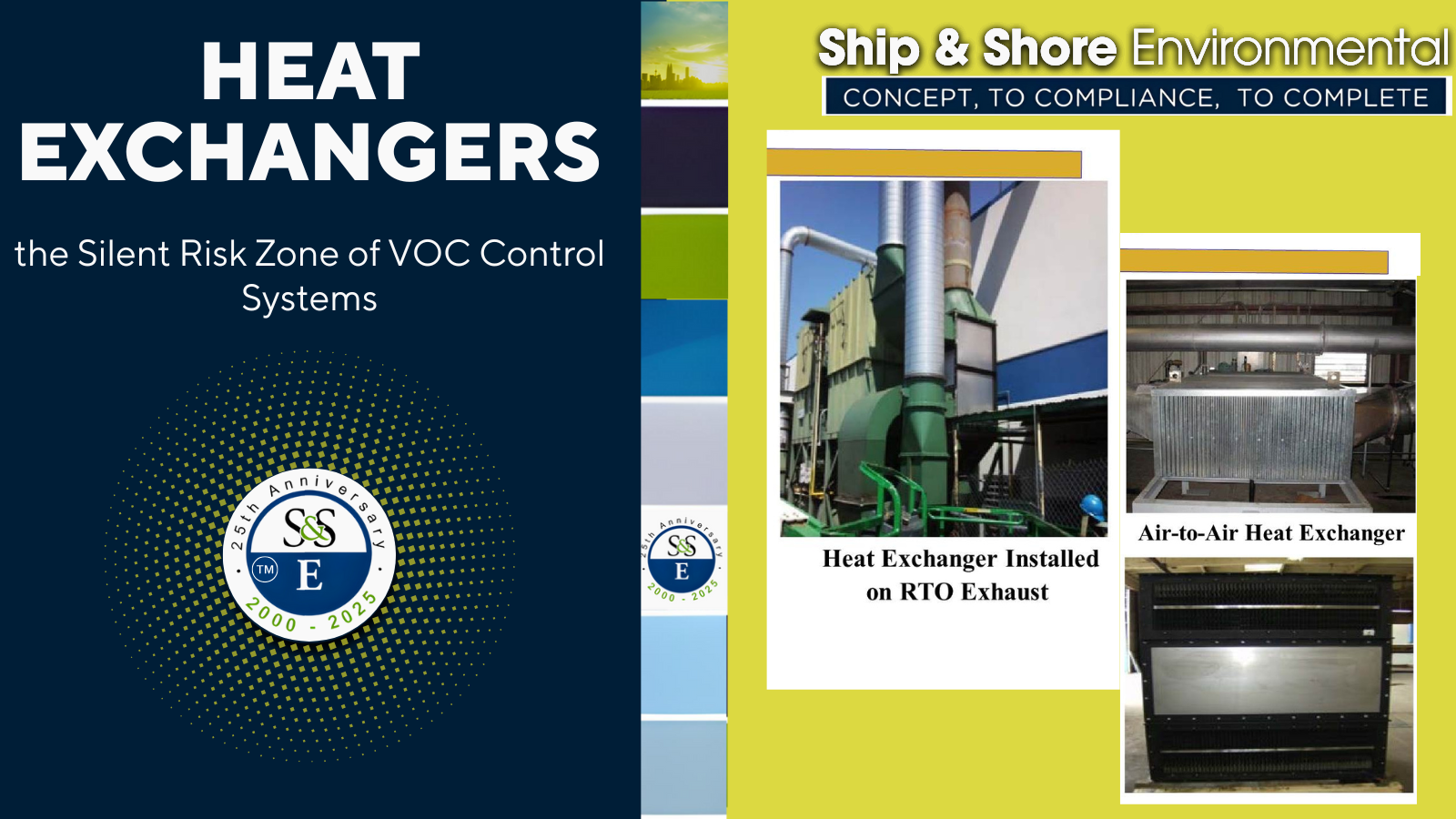

Heat Exchangers Are Silent Risk Zones in VOC Control Systems

You don’t notice a heat exchanger VOC system failing until it’s already costing you.

That’s what makes them dangerous.

Hidden behind the thermal oxidizer, heat exchangers reclaim energy and reduce fuel use across every cycle.

But when they foul, clog, or corrode, that efficiency disappears — quietly, over time.

Why we See Heat Exchangers VOC Systems Fail?

Even high-efficiency stainless steel and Inconel exchangers aren’t immune to buildup.

Particulate-laden exhaust, improper shutdown sequences, or moisture in the system can all accelerate fouling.

The result?

- Restricted airflow.

- Increased back pressure.

- And a combustion chamber that has to burn more fuel to maintain temperature.

What most operators don’t realize is that every 1% drop in recovery adds up.

A slow loss in performance doesn’t trigger alarms — it just drives up cost.

What S&SE Recommends

At Ship & Shore, we perform full thermal audits and exchanger inspections during our aftermarket service visits.

We look for surface degradation, temperature imbalance, and telltale pressure signals that indicate a fouled path.

In many cases, we can clean and restore heat exchangers before replacement is necessary.

In others, we offer retrofit upgrades — engineered to match your VOC profile and restore full thermal efficiency.

We’ve helped clients recover as much as 20% lost fuel efficiency through exchanger service alone.

What to Do Now

If your oxidizer is burning more gas than it did last year — and you haven’t checked your exchanger — it’s time.

You don’t need to guess. You need to inspect, evaluate, and decide what’s next.

Prevent Downtime. Protect Permits.

We’ve helped industrial clients across coatings, composites, food processing, and packaging industries restore heat exchanger efficiency and save thousands in energy spend.- just to name a few

One client in packaging saw a 19% reduction in gas use after we cleaned and upgraded their air-to-air heat exchanger.

Ready for a Performance Check?

Schedule your heat exchanger performance inspection here – Download Service Form

Let’s catch issues before they cost you in fuel, fines, or failures.

Contact us to schedule your inspection or get a quote.

25 Years of Clean Air Solutions — Custom Engineered, Customer Focused, Concept to Compliance to Complete.

www.shipandshore.com | info@shipandshore.com | (562) 997-0233

#HeatExchangerHealth #AftermarketSupport #VOCcontrol #IndustrialMaintenance #ComplianceReady #ShipAndShoreEnvironmental

Tags: AftermarketMonday, regenerative thermal oxidizers, Ship and Shore Environmental, VOC abatementCategorised in: #CleanAirSolutions, #MadeInAmerica, #VOC Control, 25Years of S&SE, AM Monday, RTO, RTO_Components, Ship & Shore, Technology, ThermalOxidizer, VOC Abatement