A Breath of Fresh Air

Why keeping the air clean is more crucial than ever before. The following examines the balance between specialized printing and sustainability practices.

Multicolored, high gloss, laminations, and dimensional printing techniques move merchandise off the shelves, as packaging industries seek to gain a competitive advantage. Ink or coating materials are chosen to create a best finish effect and print durability. Solvent-based or water-based coating materials are typically used, and although both coating types contain solvent material, water-based materials contain significantly less. As a large-emitter of VOCs, solvent-based printing is the focus of regulatory agencies.

The Solution

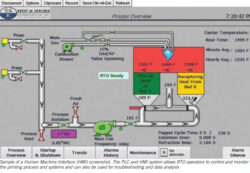

Ship & Shore Environmental (S&SE) is a supplier of VOC abatement equipment for the printing industry with complete engineering, design, fabrication, and maintenance capabilities. Thermal Oxidizers are add-on abatement controls that mitigate coating emissions in a cost-effective way. Regenerative Thermal Oxidizers (RTOs) have around 98–99% destruction efficiency and thermal efficiency of up to 97%. RTOs are usually the preferred technology within the printing industry because they can effectively control very high volumes of air with low to moderate solvent concentrations. In addition, due to the high rates of thermal effectiveness, RTOs will have minimum natural gas consumption and lower costs of operation, thereby offsetting capital equipment costs over a shorter period of time in comparison to alternate technologies. RTOs are reliable, durable, easy to maintain, and PLC controlled with a touch screen HMI interface.

Selection of a Thermal Oxidizer

The key to a successful system implementation starts with an understanding of your individual process and goals. This allows for maximum value throughout the entire equipment selection process. Read below to find out what to keep in mind during this process and how Ship & Shore Environmental can assist you.

Keys to getting best project value:

- Complete understanding of the print process maximizes abatement equipment potential

- Familiarity with all different process equipment suppliers (such as presses, laminators, ink/solvent providers) provides added advantage for any expansion and production projections for future growth

- Researching possible secondary process heat recovery opportunities to maximize energy recovery for overall lower operating costs

- Knowledge, experience, and relationships to take advantage of new construction incentive available through local state agencies and utility entities (these are very lucrative returns available primarily through highly efficient Ship & Shore RTO purchases)

- Overall assessment of plant design to maximize incentive potentials with respect to presses/laminators/RTOs as a complete package

S&SE Capabilities:

- The S&SE team is knowledgeable and up to date on current air quality regulations, so they are equipped to assist with all air permitting needs.

- S&SE technology is designed and manufactured to lower operating costs by maximizing energy recovery and optimizing airflow to the oxidizer while enhancing fuel to the unit.

- Provisions anticipating future process changes are incorporated into the design of all S&SE units.