Twin 3-Chamber RTO and Dust Collector for Paint Facility Air Pollution Control in China

April 2, 2024 10:42 amTwin 3-Chamber RTO and Dust Collector System for Air Pollution Abatement in a Paint Production Facility in China

System Overview

- System Name and Type: Twin 3-Chamber Regenerative Thermal Oxidizer (RTO), Dust Collectors with Collection Duct System.

- Purpose and Location: The system was installed to abate air pollutant emissions from a paint production facility located in ZhangJiaGang City, JiangSu Province, China. Its primary function is to reduce the emission of volatile organic compounds (VOCs), dust, xylene, and paint vapor from the manufacturing processes, ensuring compliance with environmental regulations and improving air quality in the region.

Design and Components

- Key Components and Materials: The system comprises a combination of Dust Collectors and Twin 3-Chamber Regenerative Thermal Oxidizers (RTOs), designed to effectively capture and destroy air pollutants. Materials used in the construction are selected for durability and resistance to harsh environmental conditions.

Design Specifications

- VOC Collection System: The system is designed to handle a maximum extraction rate of 160,000 m³/h, effectively capturing VOCs.

- Concentration: The system maintains a VOC concentration of 800 to 10,500 mg/m³, ensuring compliance with emission regulations.

- Safety Measures: The design incorporates several safety features to prevent accidents and ensure operator safety:

Water spray and drainage system to extinguish fires inside the active carbon tank.

Safety grids at the outlet of rotary valves and the inlet of fresh air dampers to prevent unwanted access.

Proximity sensors to enhance operator safety during dust barrel emptying.

Normal Operating Conditions and Ranges

- Ambient Conditions: The system operates in a wide range of temperatures, from -14.8ᵒC to 38ᵒC, with an average temperature of 15.5ᵒC. The facility’s location has an altitude of 12 meters and experiences wind speeds ranging from 3.5m/s on average to a maximum of 20m/s. VOC off-gas humidity is maintained below 85%.

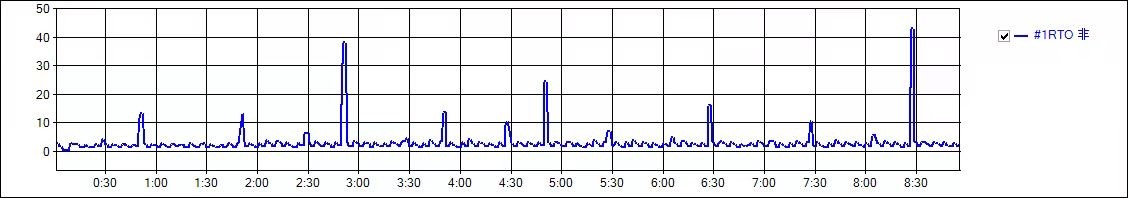

Monitoring and Control Methods

The system is equipped with an HMI (Human-Machine Interface) screen on the control cabinet that allows remote monitoring, control, and adjustments. The control room and cabinets are designed to be explosion-proof, ensuring safety in potentially hazardous environments.

Emissions Control

- Types of Targeted Pollutants: The system is primarily designed to control and reduce the emissions of dust, xylene, and paint vapor, with a particular focus on VOCs.

- Removal Efficiency and Compliance: The system achieves a high removal efficiency of 99% for VOCs, ensuring that the emissions from the paint production process are well within regulatory compliance limits.

Maintenance and Upkeep

- Routine Maintenance Requirements: The maintenance of the system is scheduled based on production and environmental conditions, ensuring it remains effective at all times.

Component Replacement Frequency

- Ceramic Media: Estimated to have a lifespan of 15 years.

- Pre-filter Bags of RTO: Typically replaced annually, with adjustments made as per production conditions.

- Filter Bags of Dust Collector: Replaced annually, adjusted based on production conditions.

- Active Carbon Equipment Charcoal: Replacement scheduled once a year, influenced by production conditions.

Performance Data

- Historical Emissions Reduction and Efficiency Data: The system has consistently achieved a 99% reduction in VOC emissions, ensuring that the facility complies with environmental regulations and maintains a commitment to reducing its environmental footprint. Over its operational history, it has significantly improved air quality in the ZhangJiaGang region, contributing to a cleaner and healthier environment.

This case study highlights the successful implementation of a state-of-the-art air pollution control system, emphasizing the importance of efficient design, rigorous safety measures, and ongoing maintenance to ensure compliance with environmental regulations and minimize the environmental impact of industrial processes.

Categorised in: Air pollution, Industry news, News, News, Ship & Shore, VOC Abatement