Catalytic Oxidizer

Performance Testing and Efficiency

Catalytic Oxidizers are equipped with a bed of catalyst blocks or beads which lose performance over time and have to be tested in the laboratory. The destruction efficiency decreases and compliance with your air permit is endangered. Facility, Operation, and Maintenance Managers who are on a tight budget try to avoid investing in new catalyst beds by increasing the operating temperature of their Catalytic Oxidizer – the only way to stay in compliance for the next upcoming emission test.

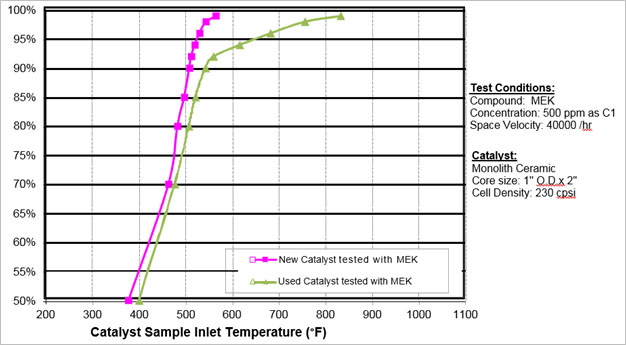

The curves show the laboratory test comparison of the new (magenta) Catalyst destruction efficiency compared to the used (green) Catalyst destruction efficiency from your Catalytic Oxidizer bed. New Catalyst performs at 550°F with 98% destruction efficiency, used Catalyst needs more than 760°F to get to the 98% destruction efficiency.

Ship & Shore Environmental can provide assistance to analyze the energy efficiency of your system. We can replace your Catalytic Oxidizer and avoid expensive catalyst replacements or inefficient operation and upgrade to more energy efficient Regenerative Thermal Oxidizers.

For more Ship & Shore environmental engineering insights and technical information, please contact sales@shipandshore.com