CASE STUDY – Integrated VOC Abatement System for a Flexographic Printing Facility

February 4, 2026 9:52 amCASE STUDY: Integrated VOC Abatement System for a Flexographic Printing Facility

February 4, 2026

Facility Background

A high-output flexographic printing facility operating multiple presses and laminators required an upgraded VOC control system. Production expansion and new converting equipment increased exhaust volumes and solvent loads, challenging existing controls and regulatory compliance. The facility needed a solution that ensured continuous compliance, maintained uptime, and improved energy efficiency without disrupting operations.

Technical Challenges

Emissions originated from multiple sources, including press dryers, laminators, and zone exhaust lines, each with variable flow and solvent composition. Streams contained alcohol, ketones, and aromatic compounds, requiring high-temperature oxidation. Space constraints and future equipment additions demanded a compact, modular, and scalable solution with minimal maintenance and high thermal efficiency.

Engineering Assessment & Design Basis

S&SE performed on-site and desktop evaluations, including airflow verification, exhaust mapping, and review of ink and solvent data. Process inlet temperatures (~120°F) and solvent heating values (~14,500 BTU/LB) guided the thermal design. The objective was stable destruction efficiency above 98% under variable conditions while minimizing supplemental fuel demand.

S&SE Abatement Solution

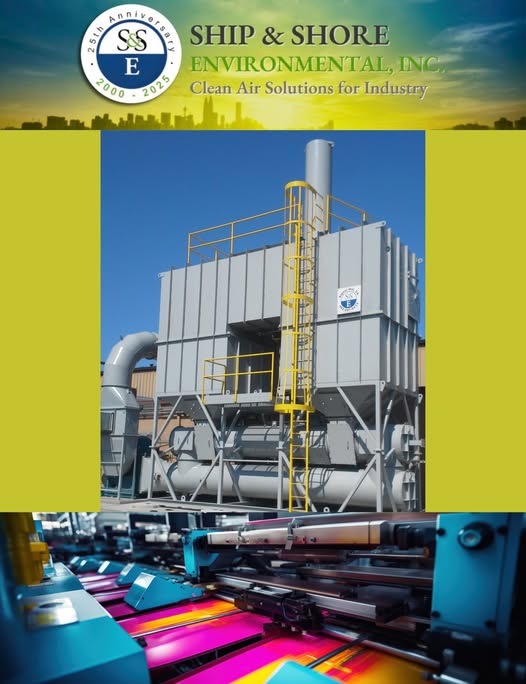

S&SE engineered two 25,000 SCFM regenerative thermal oxidizers (RTOs) capable of parallel or independent operation.

The system manages emissions from:

- One existing press (~8,000 SCFM)

- One new press (~8,000 SCFM)

- Two laminators

- Zone exhaust lines (~800–1,000 SCFM each)

The RTOs feature high-efficiency ceramic heat exchange media, low-NOx combustion, and single cylinder poppet valves for reliable operation. The system maintains stable oxidation, destruction efficiency >98%, thermal effectiveness ~95%, and accommodates future equipment, including optional ozone treatment.

Mechanical & Controls Features

RTO chambers use heavy-gauge steel with reinforced framing and multiple access doors for inspection and maintenance. PLC-based controls include HMI interface, multi-point temperature monitoring, safety interlocks, and optional secure remote diagnostics. Pre-wired subassemblies simplify field installation and reduce setup time.

Results

The system delivers consistent VOC destruction, high thermal efficiency, and stable operation across variable press schedules. Parallel operation ensures redundancy, while regenerative heat recovery and adaptive airflow reduce energy use. The facility achieved reliable compliance and a scalable abatement platform for future growth.

📞 Contact us at +1 (562) 997-0233

📧 Email: service@shipandshore.com

Categorised in: Case Study & White Papers, News, News, VOC Abatement