A single process to handle hydraulic fracturing produced water and offgases

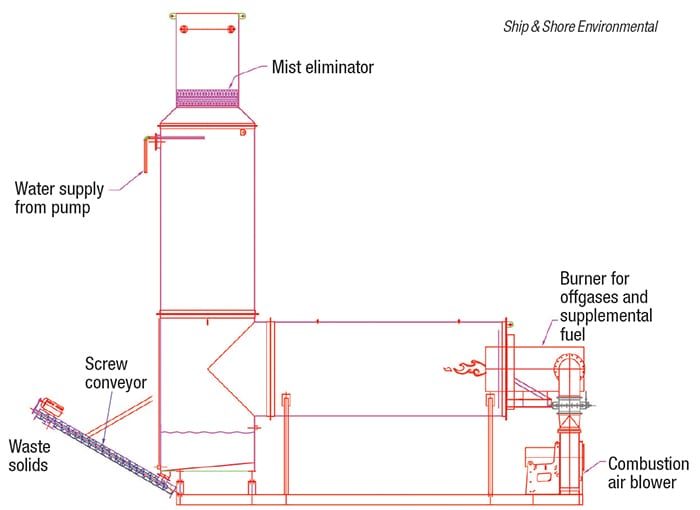

March 6, 2019 10:20 amTwo major concerns in hydraulic fracturing operations are finding efficient ways to handle the massive amount of produced wastewater, and dealing with offgases from the well. A new technology developed by Ship & Shore Environmental Inc. (Signal Hill, Calif.; www.shipandshore.com), in partnership with Hydrozonix LLC (Conroe, Tex.; www.hydrozonix.com), employs an enclosed flare to destroy the well offgases and harvests the resulting energy to evaporate wastewater. According to Mike Pawlowski, senior technical sales manager at Ship & Shore Environmental, this the first technology available to the hydraulic fracturing market for onsite evaporation of produced water. The process — called Hydroflare — works by connecting the source of well offgases to an enclosed flare burner. “The resultant heat from the flare is passed to a tower or stack, which includes spray nozzles to mist the produced water into the high-temperature discharge of the burner section,” explains Pawlowski. A conveyor is also provided to discharge any solids present in the liquid stream for solid-waste disposal.

The Hydroflare technology will be especially useful for hydraulic fracturing sites that have difficulty in removing wastewater via trucks, or those that must use enclosed flares to treat offgases, says Pawlowski. The Hydroflare enclosed flare is said to achieve a destruction efficiency for offgases of 99% or higher. Pawlowski notes that water disposal capacity is limited to the amount of offgas present or by the availability of supplemental fuel. The technology can be “dropped in” to existing sites, provided that ground support and proper utilities are in place. The first Hydroflare system was recently installed at a 1,000-bbl/d production site in Texas.